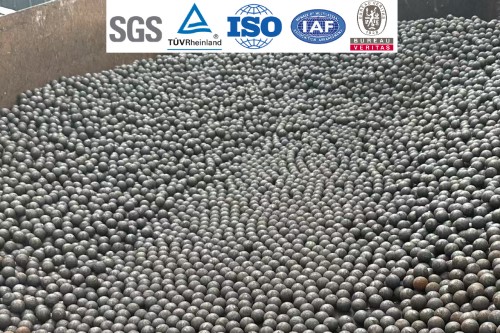

Zenti Ball Mill Grinding Steel Ball for Gold Mine

The 5 Inch Forged Grinding Ball is crafted through advanced forging and heat treatment technology, providing exceptional hardness, uniform density, and long-lasting wear resistance. Each ball offers outstanding impact toughness and maintains its roundness even after extensive grinding cycles. With precise control of carbon and alloy content, our balls ensure stable performance, minimal wear, and high energy efficiency in mineral processing plants.

Product Range Overview

Our forged grinding balls are manufactured using premium alloy steel materials, processed under high-temperature forging and controlled quenching systems. The final product achieves consistent hardness from surface to core, making it suitable for heavy-duty grinding applications in ball mills. Sizes range from 1 inch to 5 inches, meeting diverse industrial needs and maintaining high reliability under continuous operation.

Application Insights

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Zenti’s 5 Inch Forged Grinding Ball is widely used in gold, copper, iron, and nickel ore grinding, as well as in cement and power plants. It performs efficiently in both dry and wet grinding conditions, reducing energy consumption and improving production efficiency. Its durability and consistent quality make it a preferred choice for large-scale mining operations worldwide.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Quality Management System

At Jinan Zenti Heavy Industry, every forged ball undergoes a comprehensive inspection process. Tests include surface hardness measurement, core hardness analysis, impact testing, and drop testing from controlled heights. These strict evaluations ensure the product meets international mining standards for toughness and wear resistance, guaranteeing safety and reliability in demanding working environments.

Manufacturing Process

Exhibition Highlights

Zenti actively participates in global mining exhibitions such as Mining Week (Mongolia), MinExpo Africa (Tanzania), and MiningMetals Central Asia (Kazakhstan). Through these events, we present our advanced grinding media solutions and communicate directly with clients worldwide. Each exhibition strengthens our connection with the mining community and showcases our commitment to global quality and innovation.

Cooperation Opportunities

Choosing Zenti means choosing precision, reliability, and expertise. We provide fast delivery, professional technical support, and customized solutions based on client needs. Our focus on stable quality and customer satisfaction has earned us long-term partnerships across 50+ countries. With rich experience and strict standards, Zenti is your trusted supplier for high-quality forged grinding balls.

Related News

Submitted successfully

We will contact you as soon as possible