Middle Chromium Alloy Cast Balls

Middle Chromium Alloy Cast Balls are produced using controlled sand casting or lost foam casting techniques, combined with medium chromium alloy materials typically containing 10%–13% Cr. This composition offers a balanced combination of hardness and toughness, making Middle Chromium Alloy Cast Balls well-suited for grinding medium-hard ores such as coal, cement clinker, and limestone.

Introduction of the product

Through optimized heat treatment, Middle Chromium Alloy Cast Balls achieve a stable hardness range from 48 to 55 HRC. This controlled structure ensures reliable wear resistance while maintaining sufficient impact strength to minimize breakage in rotary ball mills. Compared to low chromium balls, Middle Chromium Alloy Cast Balls show longer operational life and more consistent grinding efficiency under semi-abrasive conditions.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||||||

Name | C | Si | Mn | Cr | Mo | S | P | Cu | Ni | |

ZQCr26 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 23.0-30.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr20 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 18.0-23.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr15 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 14.0-18.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr12 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 10.0-14.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

Middle Chromium Alloy Cast Balls | ZQCr8 | 2.1-3.3 | ≤2.2 | 0.3-1.5 | 7.0-10.0 | 0-1.0 | ≤0.06 | ≤0.10 | 0-0.8 | - |

ZQCr5 | 2.1-3.3 | ≤1.5 | 0.3-1.5 | 4.0-6.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - | |

Low Chromium Alloy Cast Balls | ZQCr2 | 2.1-3.6 | ≤1.5 | 0.3-1.5 | 1.0-3.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - |

Bainite Alloy Cast Balls | ZQQTB | 3.2-3.8 | 2.0-3.5 | 2.0-3.0 | - | - | ≤0.03 | ≤0.10 | - | - |

ZQQTM | 3.2-3.8 | 2.0-3.5 | 0.5-1.5 | - | - | ≤0.03 | ≤0.10 | - | - | |

| Physical Features | |||||||

| Name | Surface Hardness (HRC) | Impact Value (J/cm²) | Breakage Rate (%) | Diameter Tolerance (mm) | Diameter (mm) | Drop Test (Times) | |

| High Chromium Alloy Cast Balls | ZQCr26 | ≥58 | ≥4J | ≤1.0 | Φ≤30 +1.0 -1.0 30<Φ≤60 +1.5 -1.0 60<Φ≤80 +2.0 -1.0 80<Φ≤100 +2.5 -1.0 Φ>100 +3.0 -1.0 | 10-160 | >15000 |

| ZQCr20 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr15 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr12 | ≥58 | ≥4J | ≤1.0 | ||||

| Middle Chromium Alloy Cast Balls | ZQCr8 | ≥48 | ≥4J | ≤1.0 | |||

| ZQCr5 | ≥47 | ≥4J | ≤1.0 | ||||

| Low Chromium Alloy Cast Balls | ZQCr2 | ≥45 | ≥4J | ≤1.0 | |||

| Bainite Alloy Cast Balls | ZQQTB | ≥50 | ≥4J | ≤1.0 | |||

| ZQQTM | ≥52 | ≥4J | ≤1.0 | ||||

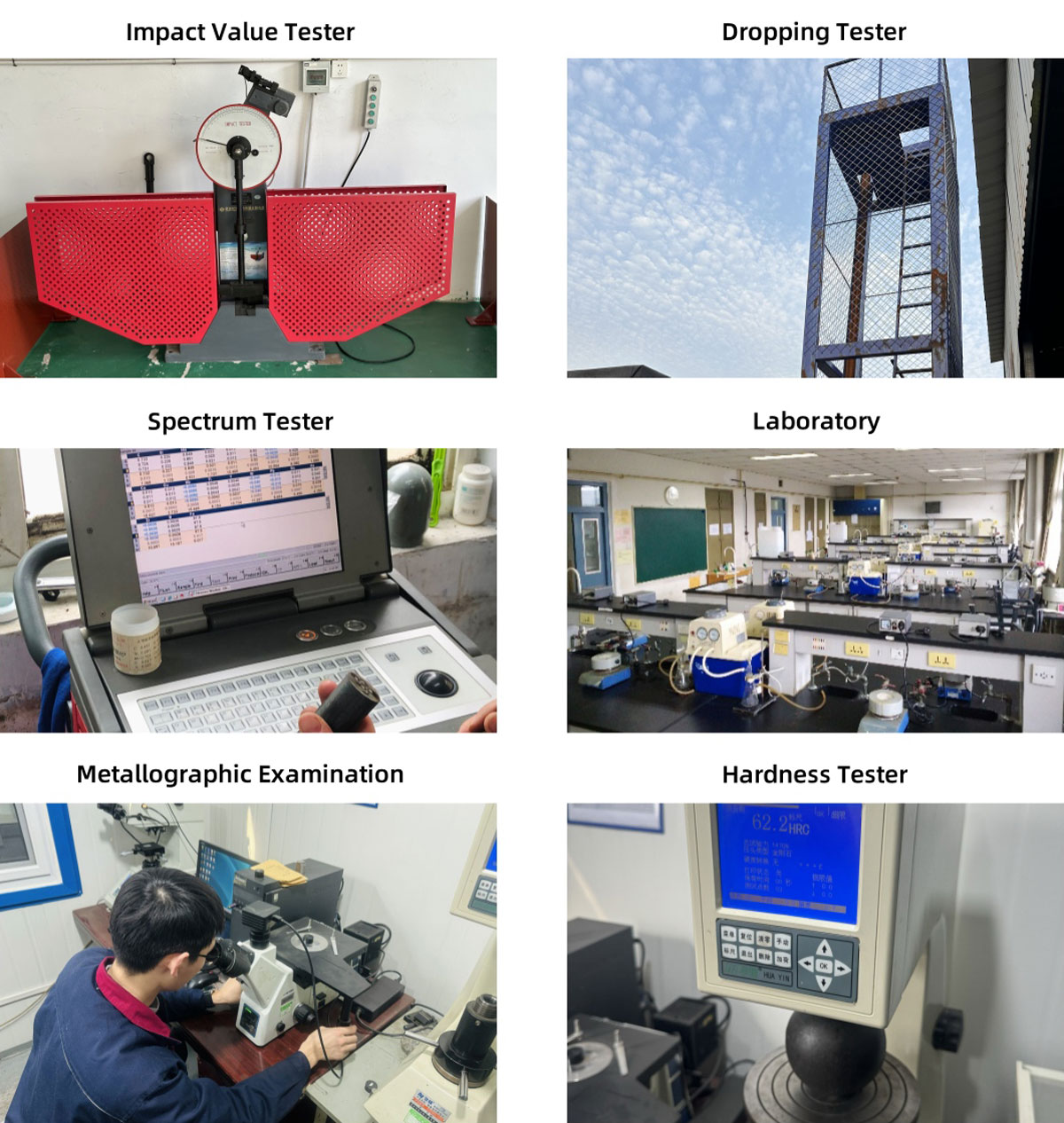

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

Each Middle Chromium Alloy Cast Ball is rigorously tested for internal defects, surface smoothness, and dimensional accuracy. With a typical diameter range from 20mm to 130mm, and support for custom sizes, these balls offer strong adaptability for both dry and wet milling environments. The alloy’s corrosion resistance also makes Middle Chromium Alloy Cast Balls a cost-effective choice for mineral plants seeking longer media lifespan and reduced consumption.

Related News

Submitted successfully

We will contact you as soon as possible