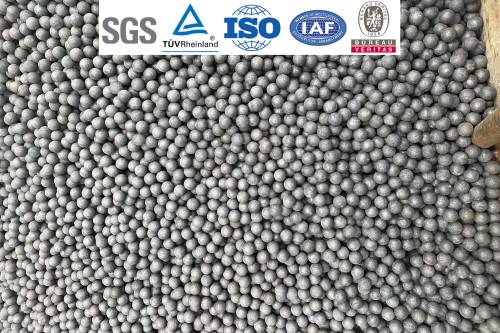

Premium Ball Mill Grinding Steel Ball for Client

The Premium Ball Mill Grinding Steel Ball is designed to deliver exceptional performance in high-load grinding operations. Manufactured with advanced forging and heat treatment processes, it offers superior hardness, balanced internal structure, and long service life. The optimized alloy composition ensures low wear, minimal deformation, and consistent grinding results, helping clients achieve greater efficiency and reduced production costs.

Product Range Overview

Each grinding ball is produced from carefully selected alloy steel and undergoes strict temperature and quenching control during manufacturing. The ball maintains uniform hardness from the surface to the core, guaranteeing excellent toughness and stability under impact conditions. With diameters ranging from 20mm to 150mm (1 inch to 5 inches), the product fits a wide range of ball mills used in mining, cement, and power industries.

Application Insights

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Zenti’s Premium Grinding Steel Balls are widely used for processing gold, copper, iron, and silver ores. They are also suitable for cement plants and power stations, offering consistent performance in both wet and dry milling environments. The high toughness and wear resistance make them ideal for large-scale mineral grinding operations, ensuring smoother mill performance and longer equipment life.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Quality Management System

Jinan Zenti Heavy Industry enforces a rigorous inspection system for every batch of grinding balls. The testing process includes hardness analysis, drop impact testing, and metallographic inspection to confirm microstructure consistency. All results comply with international mining standards, ensuring the steel balls meet client expectations for hardness, strength, and reliability during prolonged operation.

Manufacturing Process

Exhibition Highlights

Zenti actively attends major global mining exhibitions such as MINEX (Turkey), Mining Week (Mongolia), and MinExpo Africa (Tanzania). These events allow us to present advanced grinding technologies, communicate with industry professionals, and expand cooperation opportunities. Through every exhibition, we demonstrate our global vision, technological capability, and commitment to serving clients worldwide.

Cooperation Opportunities

Choosing Zenti means choosing quality, speed, and trust. We ensure fast delivery, stable production, and professional after-sales service. With over 20 years of experience and exports to 50+ countries, we have built a strong reputation among global mining enterprises. Our strict quality control, efficient logistics, and customer-first philosophy make Zenti a reliable partner in grinding media supply.

Related News

Submitted successfully

We will contact you as soon as possible