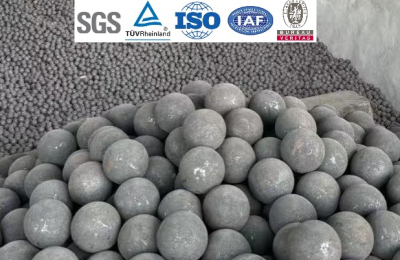

Forged Grinding Ball for Mining

The Forged Grinding Ball for Mining is produced through advanced forging technology, ensuring a dense structure, uniform shape, and consistent hardness. Compared with traditional cast balls, it offers superior impact resistance and lower breakage rates, maintaining excellent stability under heavy grinding conditions. Its smooth surface and high roundness improve milling efficiency and extend the lifespan of grinding equipment.

Product Overview

High-grade alloy steels such as ZT-2, ZT-3, and ZT-4 are selected and subjected to repeated forging at high temperatures to align the metal grain structure. This process significantly enhances wear resistance and toughness. After precise quenching and tempering, the Forged Grinding Ball for Mining achieves a surface hardness of 60–66 HRC with uniform hardness from core to surface, ensuring consistent performance and long-term reliability.

Market Applications

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

The Forged Grinding Ball for Mining is widely used in gold, copper, iron, silver, and nickel ore beneficiation, as well as in cement and power plant grinding systems. Different ball diameters can be combined for various grinding stages—from coarse to fine and ultra-fine milling—ensuring optimal particle size control and improved overall efficiency.

Technical Parameters

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Quality Certification

Every Forged Grinding Ball for Mining undergoes multiple rigorous quality inspections before delivery, including hardness testing, drop tests, impact resistance checks, and metallographic analysis. Each ball must meet strict standards for dimensional accuracy, uniform hardness, and crack resistance to ensure reliable performance under prolonged and high-intensity grinding conditions.

Production Technology

Global Exhibitions

We actively participate in global mining and construction exhibitions, such as Mining Indaba (Africa), Mongolia Mining Week, Mining World Russia, MINEX Turkey, and IMARC Australia. Through direct display and communication, we help customers better understand the performance and advantages of the Forged Grinding Ball for Mining while continuously expanding our international presence and promoting brand globalization.

Business Partnership

With its outstanding performance and reliability, the Forged Grinding Ball for Mining has been adopted by leading mining companies worldwide, exported to over 50 countries across Europe, South America, Africa, Australia, and Southeast Asia. Customers consistently report reduced consumption and lower operating costs due to the ball’s low breakage rate and long service life, making it an ideal grinding media for all types of ball mills.

Related News

Submitted successfully

We will contact you as soon as possible