High Chromium Alloy Cast Balls

High Chromium Alloy Cast Balls are made from cast steel containing 15% to 30% chromium, providing excellent hardness and superior wear resistance. This high chromium content enables the balls to perform well in abrasive and high-impact grinding conditions, such as in mining and cement industries.

Product Lineup

The casting and heat treatment process results in a dense, uniform microstructure with a hardness typically ranging from 58 to 65 HRC. This ensures long service life and reduced media consumption, lowering operational costs for grinding mills.

Application Overview

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||||||

Name | C | Si | Mn | Cr | Mo | S | P | Cu | Ni | |

High Chromium Alloy Cast Balls | ZQCr26 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 23.0-30.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 |

ZQCr20 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 18.0-23.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr15 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 14.0-18.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr12 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 10.0-14.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

Middle Chromium Alloy Cast Balls | ZQCr8 | 2.1-3.3 | ≤2.2 | 0.3-1.5 | 7.0-10.0 | 0-1.0 | ≤0.06 | ≤0.10 | 0-0.8 | - |

ZQCr5 | 2.1-3.3 | ≤1.5 | 0.3-1.5 | 4.0-6.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - | |

Low Chromium Alloy Cast Balls | ZQCr2 | 2.1-3.6 | ≤1.5 | 0.3-1.5 | 1.0-3.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - |

Bainite Alloy Cast Balls | ZQQTB | 3.2-3.8 | 2.0-3.5 | 2.0-3.0 | - | - | ≤0.03 | ≤0.10 | - | - |

ZQQTM | 3.2-3.8 | 2.0-3.5 | 0.5-1.5 | - | - | ≤0.03 | ≤0.10 | - | - | |

| Physical Features | |||||||

| Name | Surface Hardness (HRC) | Impact Value (J/cm²) | Breakage Rate (%) | Diameter Tolerance (mm) | Diameter (mm) | Drop Test (Times) | |

| High Chromium Alloy Cast Balls | ZQCr26 | ≥58 | ≥4J | ≤1.0 | Φ≤30 +1.0 -1.0 30<Φ≤60 +1.5 -1.0 60<Φ≤80 +2.0 -1.0 80<Φ≤100 +2.5 -1.0 Φ>100 +3.0 -1.0 | 10-160 | >15000 |

| ZQCr20 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr15 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr12 | ≥58 | ≥4J | ≤1.0 | ||||

| Middle Chromium Alloy Cast Balls | ZQCr8 | ≥48 | ≥4J | ≤1.0 | |||

| ZQCr5 | ≥47 | ≥4J | ≤1.0 | ||||

| Low Chromium Alloy Cast Balls | ZQCr2 | ≥45 | ≥4J | ≤1.0 | |||

| Bainite Alloy Cast Balls | ZQQTB | ≥50 | ≥4J | ≤1.0 | |||

| ZQQTM | ≥52 | ≥4J | ≤1.0 | ||||

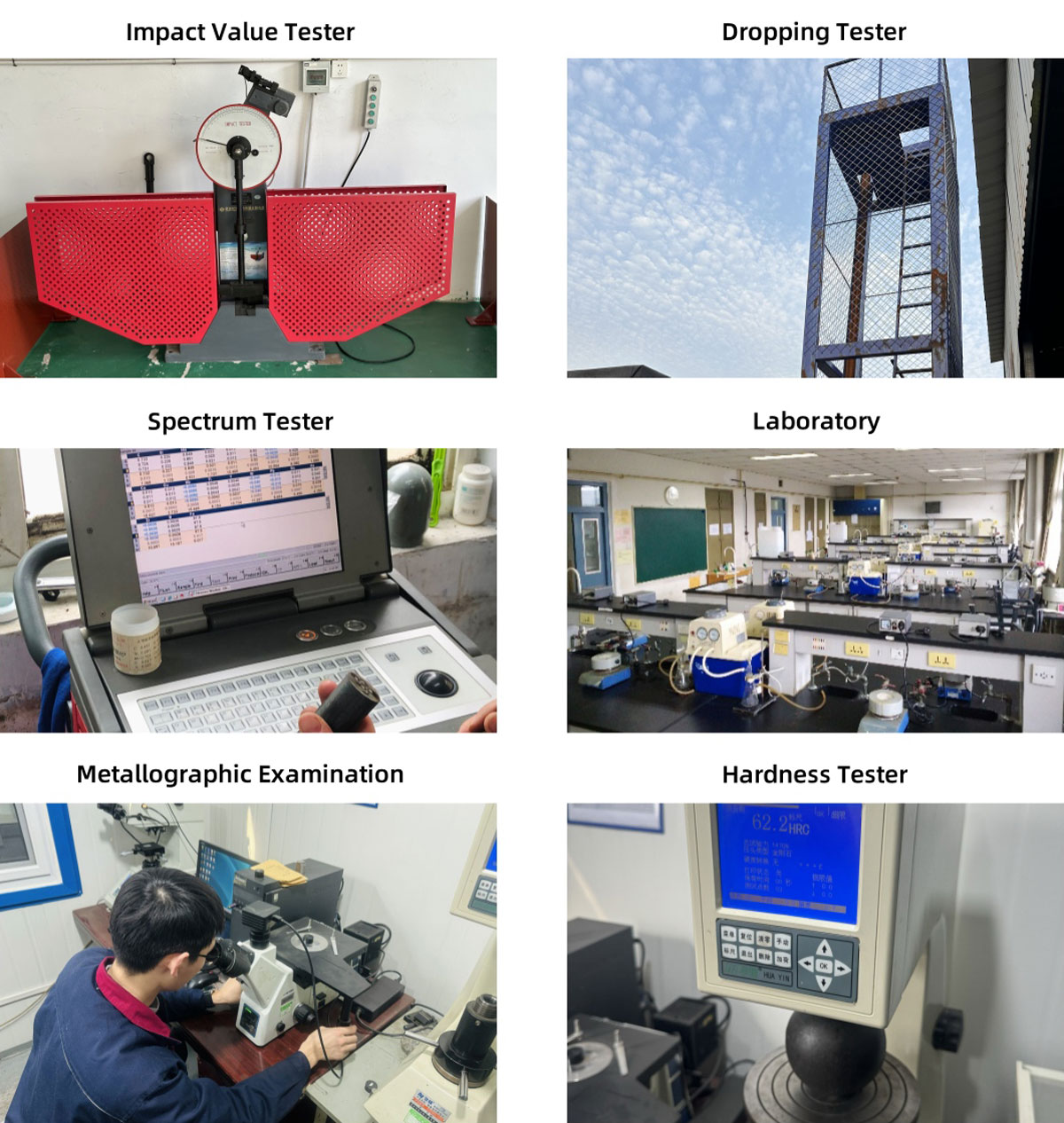

Quality Monitoring

Manufacturing Facilities

Exhibition Participation

Collaboration Opportunities

Available in a wide range of diameters (20mm to 130mm) and customizable sizes, High Chromium Alloy Cast Balls are rigorously tested for roundness, size tolerance, and surface quality. Their strong corrosion resistance and mechanical properties make them ideal for demanding grinding applications.

Related News

Submitted successfully

We will contact you as soon as possible