Forged Steel Balls Suppliers

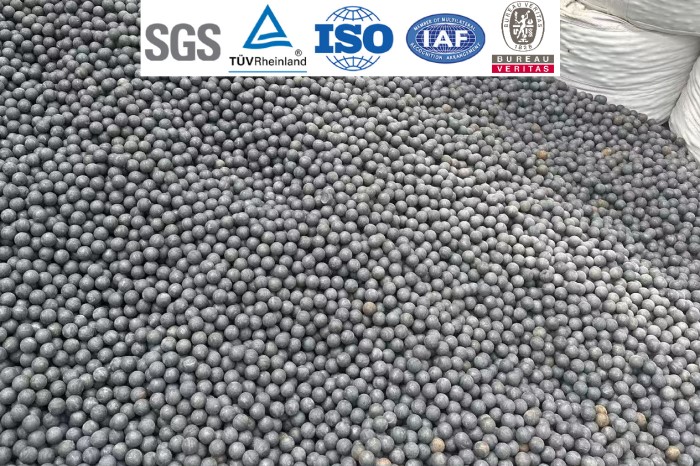

Forged Steel Balls Suppliers are recognized for offering reliable, high-performance products with strong wear resistance and impact durability. The forged balls maintain consistent shape during long-term grinding, reducing breakage and overall consumption. This enhances mill efficiency and helps mining operations lower operational costs, making these suppliers a frequent choice for durable grinding media.

Product Introduction

Forged Steel Balls Suppliers offer a wide range of sizes and diameters, suitable for various mill types and grinding conditions. Their forged balls are produced through controlled processes that ensure uniform structure and consistent movement inside the mill. The broad selection allows mining plants to match grinding media to ore characteristics and processing targets more effectively.

Wide Application

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Mining operations rely on Forged Steel Balls Suppliers for applications in gold, copper, iron, silver and other ore grinding processes. These forged balls perform consistently across various ore types, helping to minimize over-grinding and improve throughput. Whether used in primary grinding or fine milling, the products provided by these suppliers deliver dependable performance across different working conditions.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

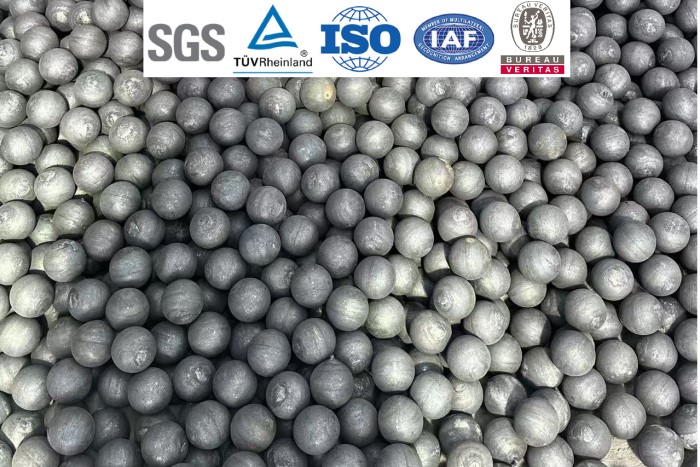

Strict Quality Inspection

Professional Forged Steel Balls Suppliers implement strict quality control throughout manufacturing, including hardness evaluation, appearance inspection, drop testing and dimensional consistency checks. This rigorous system ensures that each batch meets stable performance requirements. As a result, their forged balls perform reliably in real grinding environments, giving customers long-term confidence in product quality.

Manufacturing Process

Exhibition Presence

At major mining exhibitions, reputable Forged Steel Balls Suppliers showcase their latest products and share application insights with global customers. Through direct technical discussions, suppliers gain a deeper understanding of mining needs while strengthening brand visibility. These exhibitions help expand international partnerships and promote reliable grinding solutions to more regions

Why Choose Us

Working with trusted Forged Steel Balls Suppliers ensures consistent supply, fast response and ongoing technical support. These suppliers maintain diverse inventory options and provide configuration suggestions tailored to different mill models, enabling smoother grinding operations. With dependable quality and industry expertise, they are long-standing partners for mines seeking stable grinding media solutions.

Related News

Submitted successfully

We will contact you as soon as possible