Forged Mining Grinding Media

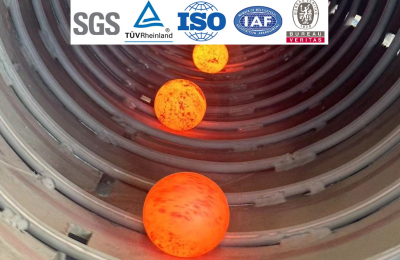

Forged Mining Grinding Media is developed to meet the long-hour operation needs of mining plants. Its forged structure allows the grinding media to handle continuous impact and rolling forces inside the mill. This helps maintain steady grinding efficiency while supporting smoother material flow during the milling process.

Product Introduction

Forged Mining Grinding Media is produced through a series of heating, shaping, and controlled cooling steps using selected steel materials. The forging method improves overall density and balance, making the media suitable for regular use in ball mills and similar grinding equipment found in mining operations.

Wide Application

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Forged Mining Grinding Media is commonly applied in gold, copper, iron, and other mineral processing projects. It can be used in both wet and dry grinding systems and performs well under different operating conditions. This flexibility allows it to support various production layouts and ore characteristics.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Strict Quality Inspection

Before shipment, Forged Mining Grinding Media is checked through standard inspection procedures. These include dimensional checks, surface observation, and basic hardness verification based on customer expectations. Such controls help ensure stable usage and reduce performance variation during milling operations.

Manufacturing Process

Exhibition Presence

Forged Mining Grinding Media is introduced to global clients through international mining exhibitions and industry trade fairs. These events provide opportunities to demonstrate application experience, exchange technical ideas, and better understand market demands, strengthening cooperation with partners from different regions.

Why Choose Us

By selecting Forged Mining Grinding Media, clients benefit from stable supply, adaptable specifications, and consistent product performance. Our focus on production continuity, practical solutions, and long-term cooperation helps mining operations maintain reliable grinding processes across different working environments.

Related News

Submitted successfully

We will contact you as soon as possible