1-5'' Forged Grinding Ball for Gold Mine

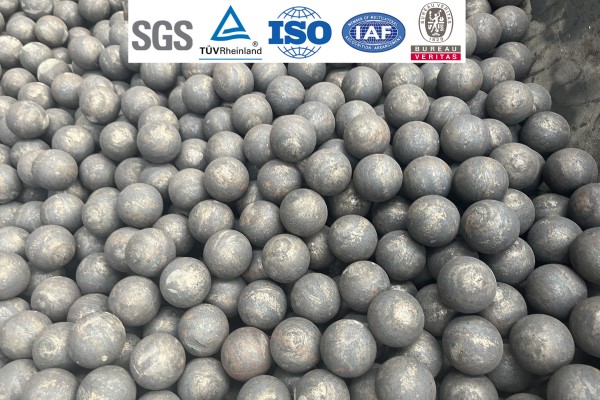

The 1-5'' Forged Grinding Ball for Gold Mine is engineered with high-quality alloy steel to ensure exceptional hardness, impact resistance, and wear performance. Each ball undergoes precision forging and controlled heat treatment, resulting in uniform structure and excellent toughness. With low breakage rates and consistent grinding efficiency, it is ideal for long-term use in gold ore milling operations where durability and stability are critical.

Product Introduction

Manufactured by Jinan Zenti Heavy Industry, our forged grinding balls are produced under strictly monitored temperature and quenching parameters. The sizes range from 1 inch to 5 inches, meeting the needs of various ball mills. Through advanced forging technology, the steel balls achieve a perfect balance of hardness and strength, offering superior performance in both wet and dry grinding processes used in gold mining.

Wide Application

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Zenti’s forged grinding balls are widely used in gold, copper, and iron mines, as well as in cement and thermal power plants. The stable hardness and impact resistance allow them to perform efficiently even under high-impact working conditions. Their excellent wear resistance reduces ball consumption and maintenance costs, making them a preferred choice for mining companies seeking cost-effective grinding media solutions.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

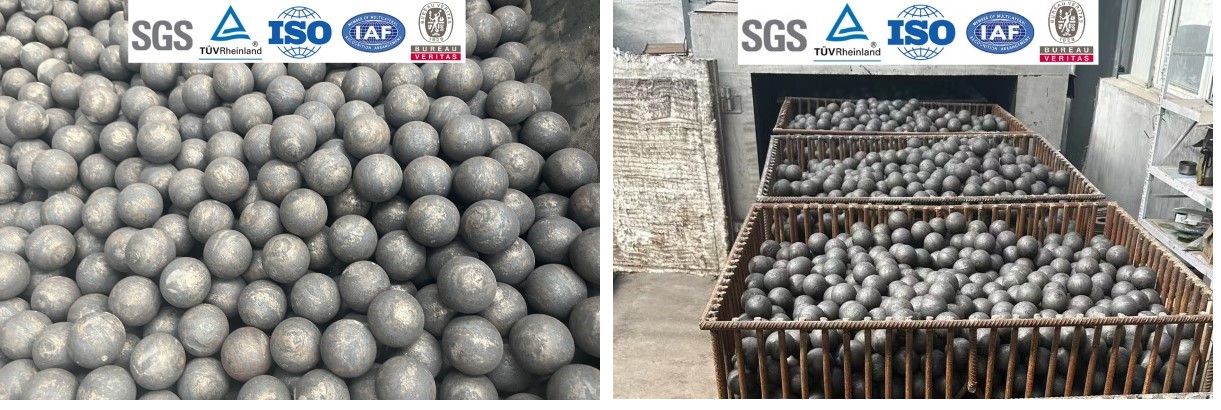

Strict Quality Inspection

Zenti places strong emphasis on quality assurance. Each batch of forged balls undergoes strict hardness testing, impact toughness measurement, and drop tests to ensure compliance with international mining standards. Our laboratory closely monitors metallographic structures and mechanical properties, guaranteeing that every steel ball meets customer requirements for strength, hardness, and performance reliability.

Manufacturing Process

Exhibition Presence

Zenti actively participates in major global mining exhibitions, including Mining Week (Mongolia), MinExpo Africa (Tanzania), and MiningMetals Central Asia (Kazakhstan). These events provide opportunities for showcasing our grinding solutions, exchanging technical expertise, and establishing long-term partnerships with mining professionals from around the world. Through exhibitions, Zenti demonstrates innovation, reliability, and global vision.

Why Choose Us

Choosing Zenti means choosing consistency and trust. With more than 20 years of production experience, we have established long-term cooperation with clients in over 50 countries. We provide quick delivery, stable supply, and professional technical support. Zenti’s forged grinding balls have earned a solid reputation for quality and dependability, making us your reliable partner for gold mine grinding solutions.

Related News

Submitted successfully

We will contact you as soon as possible