Grinding Ball Mill for Mining

Grinding Ball Mill for Mining is designed to deliver stable grinding performance under continuous operation. Its structure supports efficient energy use while maintaining consistent output. The system helps reduce unnecessary wear during long working cycles, allowing mining operations to run smoothly with predictable results and improved production efficiency.

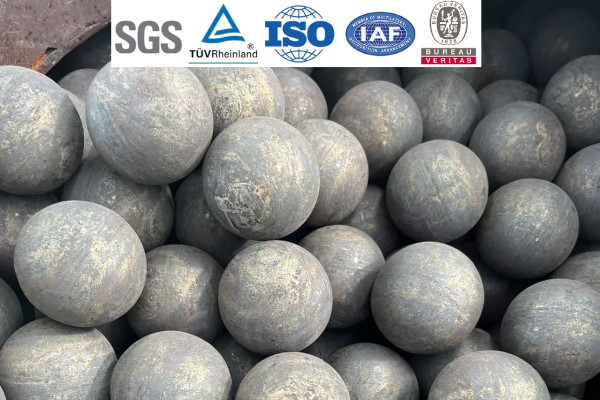

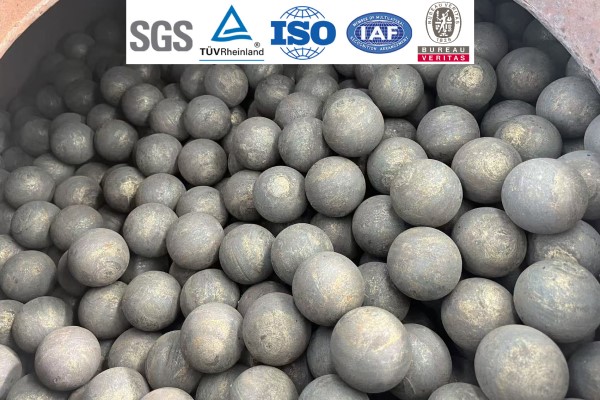

Product Introduction

Grinding Ball Mill for Mining is commonly used in mineral processing plants for size reduction and material preparation. Built with durable components and a practical design, it works well with forged grinding balls of various sizes. The mill is suitable for handling different ore types and adapts easily to changing production demands.

Wide Application

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Grinding Ball Mill for Mining is widely applied in gold, copper, iron, and other metal mining projects. It supports both dry and wet grinding processes and can be integrated into different production lines. This flexibility makes it suitable for small mines as well as large-scale mining operations worldwide.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Strict Quality Inspection

Each Grinding Ball Mill for Mining is inspected during manufacturing and before delivery to ensure stable operation and structural reliability. Key components are checked for strength and assembly accuracy, helping reduce downtime and maintain consistent grinding performance throughout daily mining operations.

Manufacturing Process

Exhibition Presence

Grinding Ball Mill for Mining is regularly introduced at international mining exhibitions and industry events. Through exhibitions, clients can better understand its working principles, application scenarios, and compatibility with different grinding media, strengthening communication and cooperation with global partners.

Why Choose Us

Choosing Grinding Ball Mill for Mining means selecting a solution focused on reliability, adaptability, and long-term use. With stable production capacity, practical design concepts, and responsive service support, we help mining clients achieve steady operation and sustainable development across different mining environments.

Related News

Submitted successfully

We will contact you as soon as possible