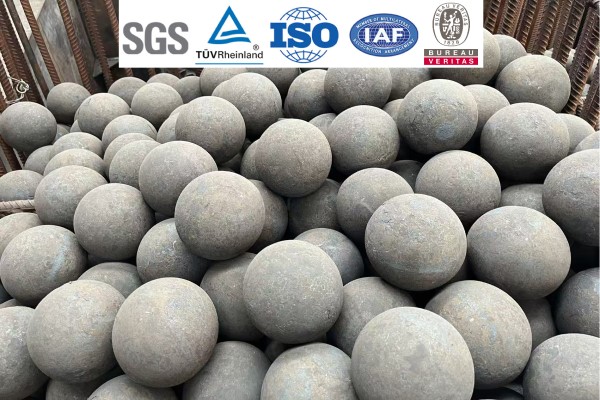

Forged Steel Mining Ball for Mine

Forged Steel Mining Ball for Mine offers stable performance during long-term grinding operations. Through a reliable forging process, the ball maintains good balance between strength and durability, helping reduce abnormal wear. This advantage supports continuous milling and contributes to smoother operation in demanding mining environments.

Product Introduction

Forged Steel Mining Ball for Mine is manufactured from selected steel materials and shaped through controlled heating and forging. The production method ensures consistent structure and uniform size, making the grinding ball suitable for use in various ball mills. It is designed to meet the general needs of modern mining operations.

Wide Application

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Forged Steel Mining Ball for Mine is widely used in gold, copper, iron, and other mineral processing plants. It performs well in both dry and wet grinding systems and adapts to different ore characteristics. This wide applicability allows it to be used across multiple mining sites and processing stages.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Strict Quality Inspection

Each batch of Forged Steel Mining Ball for Mine undergoes routine inspection before delivery. Basic checks such as size consistency, surface condition, and hardness range are carried out to meet customer requirements. This quality control process helps ensure stable performance during actual milling operations.

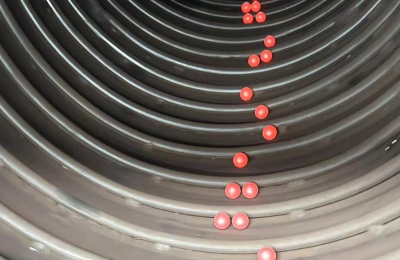

Manufacturing Process

Exhibition Presence

Forged Steel Mining Ball for Mine is frequently presented at international mining exhibitions and industry trade shows. Through direct communication at exhibitions, clients gain a clearer understanding of product features and application scenarios, strengthening cooperation and trust in long-term mining projects.

Why Choose Us

Choosing Forged Steel Mining Ball for Mine means choosing a dependable grinding solution backed by stable production and practical experience. With consistent supply capability, flexible specifications, and responsive service, we support mining clients worldwide in maintaining efficient and reliable milling operations.

Related News

Submitted successfully

We will contact you as soon as possible