Grinding Balls Mining

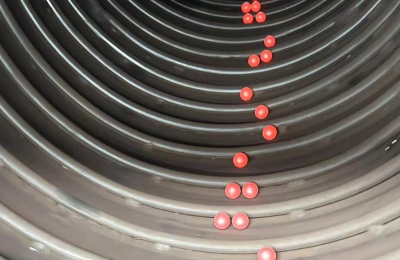

Grinding Balls for Mining offer stable hardness, strong impact resistance, and long service life, making them suitable for heavy-load mineral processing. Their consistent performance helps reduce ball consumption, improve grinding efficiency, and maintain reliable operation inside ball mills. With uniform roundness and smooth surface quality, they enhance ore breakage and overall milling output.

Product Introduction

ZenTi produces mining grinding balls through controlled forging or hot-rolling processes, ensuring even internal structure and excellent toughness. Available in a wide range of diameters, these balls can be used in various mill types and meet common mining requirements. Each ball is manufactured with stable material quality and balanced heat treatment to support long-term grinding operations.

Wide Application

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Mining grinding balls are widely used in gold, copper, iron, and other metal mines, as well as cement and power plant grinding systems. They perform well in both dry and wet milling environments, maintaining their hardness and shape during continuous operation. Their strong wear resistance makes them suitable for large-scale mineral grinding lines.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Strict Quality Inspection

ZenTi follows comprehensive quality control procedures that include hardness testing, drop tests, impact resistance checks, and surface inspections. Each batch is evaluated to ensure stable mechanical performance and low breakage rates. By maintaining strict quality standards, ZenTi ensures that every mining grinding ball meets customer expectations for durability and efficiency.

Manufacturing Process

Exhibition Presence

ZenTi actively participates in international mining exhibitions in Africa, Asia, and South America to showcase grinding media solutions. These events help us communicate with global clients, share product updates, and build strong cooperation with mining companies. Exhibitions also allow ZenTi to demonstrate its commitment to long-term development in the grinding media industry.

Why Choose Us

Choosing ZenTi means choosing dependable quality, consistent supply, and reliable service. With years of experience and customers in more than 50 countries, we understand the needs of mining operations. Our production capacity, strict quality control, and fast delivery ensure that clients receive stable and cost-effective grinding balls for long-term use.

Related News

Submitted successfully

We will contact you as soon as possible