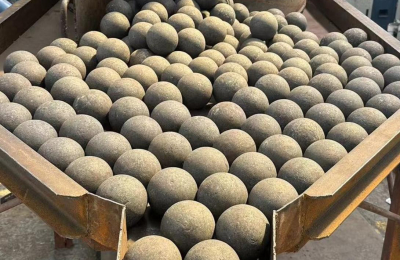

10% High Chromium Casting Ball

High Chromium Balls, which significantly enhances their hardness and wear resistance. This makes them ideal for grinding in highly abrasive environments, such as mining, cement, and chemical industries. These High Cr grinding balls achieve a high level of hardness, providing excellent performance in high-impact and high-stress grinding environments. This is particularly beneficial for grinding hard minerals and ores, improving overall grinding efficiency.

Consistent Performance:The high chromium content ensures consistent hardness and wear resistance, which translates to uniform grinding throughout their life. This leads to better product quality and more consistent particle size, enhancing the efficiency of the grinding process.

Introduction of the product

High Chromium Balls offer unmatched durability, wear resistance, and cost-effectiveness across various industries. Their superior hardness and corrosion resistance ensure consistent performance, longer service life, and enhanced grinding efficiency, making them an ideal choice for applications in mining, cement, power generation, and more. By reducing maintenance costs and improving productivity, these grinding balls provide significant long-term value to businesses.

Application in grinding machines and areas

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||||||

Name | C | Si | Mn | Cr | Mo | S | P | Cu | Ni | |

High Chromium Alloy Cast Balls | ZQCr26 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 23.0-30.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 |

ZQCr20 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 18.0-23.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr15 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 14.0-18.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

ZQCr12 | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 10.0-14.0 | 0-3.0 | ≤0.06 | ≤0.10 | 0-1.2 | 0-1.5 | |

Middle Chromium Alloy Cast Balls | ZQCr8 | 2.1-3.3 | ≤2.2 | 0.3-1.5 | 7.0-10.0 | 0-1.0 | ≤0.06 | ≤0.10 | 0-0.8 | - |

ZQCr5 | 2.1-3.3 | ≤1.5 | 0.3-1.5 | 4.0-6.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - | |

Low Chromium Alloy Cast Balls | ZQCr2 | 2.1-3.6 | ≤1.5 | 0.3-1.5 | 1.0-3.0 | 0-1.0 | ≤0.10 | ≤0.10 | 0-0.8 | - |

Bainite Alloy Cast Balls | ZQQTB | 3.2-3.8 | 2.0-3.5 | 2.0-3.0 | - | - | ≤0.03 | ≤0.10 | - | - |

ZQQTM | 3.2-3.8 | 2.0-3.5 | 0.5-1.5 | - | - | ≤0.03 | ≤0.10 | - | - | |

| Physical Features | |||||||

| Name | Surface Hardness (HRC) | Impact Value (J/cm²) | Breakage Rate (%) | Diameter Tolerance (mm) | Diameter (mm) | Drop Test (Times) | |

| High Chromium Alloy Cast Balls | ZQCr26 | ≥58 | ≥4J | ≤1.0 | Φ≤30 +1.0 -1.0 30<Φ≤60 +1.5 -1.0 60<Φ≤80 +2.0 -1.0 80<Φ≤100 +2.5 -1.0 Φ>100 +3.0 -1.0 | 10-160 | >15000 |

| ZQCr20 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr15 | ≥58 | ≥4J | ≤1.0 | ||||

| ZQCr12 | ≥58 | ≥4J | ≤1.0 | ||||

| Middle Chromium Alloy Cast Balls | ZQCr8 | ≥48 | ≥4J | ≤1.0 | |||

| ZQCr5 | ≥47 | ≥4J | ≤1.0 | ||||

| Low Chromium Alloy Cast Balls | ZQCr2 | ≥45 | ≥4J | ≤1.0 | |||

| Bainite Alloy Cast Balls | ZQQTB | ≥50 | ≥4J | ≤1.0 | |||

| ZQQTM | ≥52 | ≥4J | ≤1.0 | ||||

Quality Control Technology and Equipment

Plants and Production Equipment

Exhibitions

Why choose us

Our High chrome balls are tailored for different grinding needs.

Advanced heat treatment enhances longevity and performance.

Lower wear rates reduce replacement frequency and operational costs.

Professional Technical Support – Expert guidance to optimize grinding efficiency.

Related News

Submitted successfully

We will contact you as soon as possible