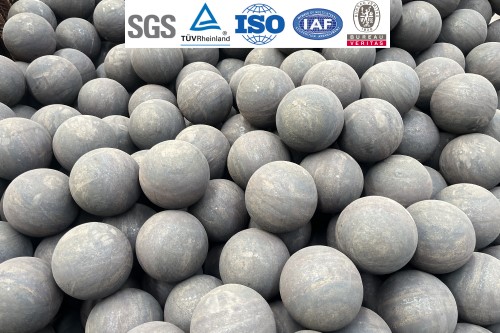

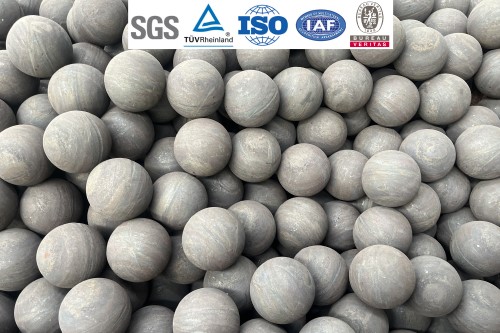

3.5 Inch Forged Grinding Balls

The 3.5 Inch Forged Grinding Balls are manufactured from proprietary alloy grades including ZT-4, ZT-2, and ZT-3, each engineered for optimal hardness, wear resistance, and impact toughness. These steel grades are processed under strict temperature control, typically between 950°C and 1050°C, using a high-pressure forging method that refines grain structure and ensures superior internal density. With a nominal size of 90mm and a unit weight of approximately 2.4 kg, the balls are ideal for high-load grinding environments such as copper and gold ore concentrators.

Product Description

Each 3.5 Inch Forged Grinding Ball is heat-treated using tailored quenching and tempering protocols specific to the selected ZT-grade alloy. This process delivers a balanced hardness profile—surface hardness ranging from 58 to 65 HRC—while retaining a tough core that resists breakage under continuous impact. Depending on the ZT material, the wear rate can be reduced by over 20% compared to standard forged balls, making these balls highly efficient for long-term use in SAG and overflow ball mills.

Applications in Grinding Machinery and Industries

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical data

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

#45/C45 | 0.42-0.54 | 0.50-0.80 | 0.17-0.37 | ≤0.15 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Advanced Quality Control Technology and Inspection Equipment

Facilities and Production Machinery

Exhibitions

Reasons to Choose Us

Strict dimensional and performance quality control is applied to all 3.5 Inch Forged Grinding Balls to ensure they meet international standards. Precision diameter tolerance (±1.0mm), excellent roundness (≤±0.8mm), and uniform microstructure are guaranteed through in-house and third-party testing. The ZT-4 grade is preferred for highly abrasive ores, ZT-2 offers a cost-effective balance of wear and toughness, while ZT-3 is suited for medium-hard ore types. These customizable materials make the 3.5 Inch Forged Grinding Balls a flexible solution for a wide range of milling circuits.

Related News

Submitted successfully

We will contact you as soon as possible