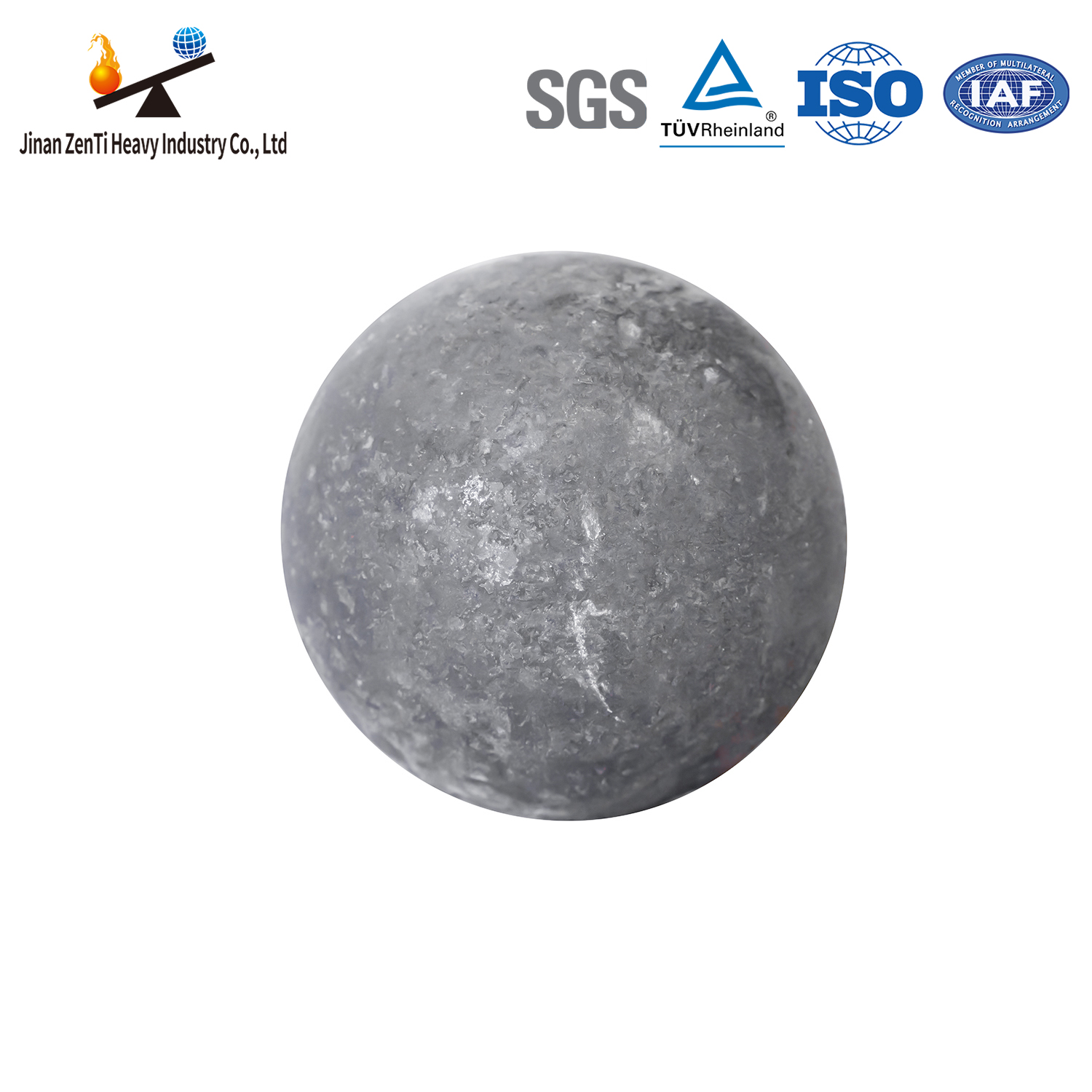

Casting Grinding Balls

Product Description:

ZenTi casting steel balls are shaped by metal mould rather than sand mould, which makes our products have stable structure, better grinding performance and uniform sizes. Our advanced producing technology and newly invested producing lines enable our products to have higher abrasion resistance and longer life. With more than 15 years of production experiences and professional services, our products have gained remarkable good feedbacks and recognization from our clients in more than 30 counties.

Application in grinding machines and areas:

·Ball mills / Vertical mills

·Mineral processing plants

·Mining industry

·Power stations

·Cement industry

·Steel Industry

Why choose us:

·High Hardness: Surface hardness: 57-66HRC, Core hardness: 43-65HRC

·Wide Sizing Range: From 10mm to 130mm.

·High Impact Value: More than 4J / cm2.

·Uniform Products: Stable structure and uniform sizes.

·Quality Control: Frequent test before delivery.

·Customized Package Service: Package in steel drums, bags, and containers.

Products features:

| General Information | |

| Product Name | Casting Grinding Balls |

| HS Code | 7325910000 |

| Size Range | 10-130mm |

| Specification | Cr (1%-32%) alloying grinding balls/ Ductile cast iron balls |

| Surface Hardness | 45-65HRC |

| Impact Value | >4J/cm2 |

| Breakage Rate (%) | ≤1% (some products lower than 2%) |

| Dropping Test | Stricter than Industrial standard |

| Packaging | Bags, Steel drums, Containers |

| Chemical Composition (%) | |||||||

| Name | C | Si | Mn | Cr | Mo | S | P |

| Cr (23-30%) alloying grinding balls | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 23.1-30.0 | ≤3.0 | ≤0.06 | ≤0.10 |

| Cr (18-23%) alloying grinding balls | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 18.1-23.0 | ≤3.0 | ≤0.06 | ≤0.10 |

| Cr (14-18%) alloying grinding balls | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 14.1-18.0 | ≤3.0 | ≤0.06 | ≤0.10 |

| Cr (10-14%) alloying grinding balls | 2.0-3.3 | ≤1.2 | 0.3-1.5 | 10.1-14.0 | ≤3.0 | ≤0.06 | ≤0.10 |

| Cr (7-10%) alloying grinding balls | 2.1-3.3 | ≤2.2 | 0.3-1.5 | 7.0-10.0 | ≤1.0 | ≤0.06 | ≤0.10 |

| Cr (4-6%) alloying grinding balls | 2.1-3.3 | ≤1.5 | 0.3-1.5 | 4.0-6.0 | ≤1.0 | ≤0.10 | ≤0.10 |

| Cr (1-3%) alloying grinding balls | 2.1-3.6 | ≤1.5 | 0.3-1.5 | 1.0-3.0 | ≤1.0 | ≤0.10 | ≤0.10 |

| Ductile cast iron balls (Bainite) | 3.2-3.8 | 2.0-3.5 | 2.0-3.0 | - | - | ≤0.03 | ≤0.10 |

| Ductile cast iron balls (Martensite) | 3.2-3.8 | 0.5-1.5 | 0.5-1.5 | - | - | ≤0.03 | ≤0.10 |

| Physical Features | |||||

| Name | Surface Hardness (HRC) | Core Hardness (HRC) | Impact Value (J/cm2) | Breakage Rate (%) | Diameter (mm) |

| Cr (23-30%) alloying grinding balls | 58-65 | 55-65 | ≥4 | ≤1.0 | 10-130 |

| Cr (18-23%) alloying grinding balls | 58-65 | 55-65 | ≥4 | ≤1.0 | |

| Cr (14-18%) alloying grinding balls | 58-65 | 55-65 | ≥4 | ≤1.0 | |

| Cr (10-14%) alloying grinding balls | 58-65 | 55-65 | ≥4 | ≤1.0 | |

| Cr (7-10%) alloying grinding balls | ≥48 | ≥45 | ≥4 | ≤1.9 | |

| Cr (4-6%) alloying grinding balls | ≥47 | ≥44 | ≥4 | ≤1.9 | |

| Cr (1-3%) alloying grinding balls | ≥45 | ≥43 | ≥4 | ≤2.0 | |

| Ductile cast iron balls (Bainite) | ≥50 | ≥48 | ≥4 | ≤2.0 | |

| Ductile cast iron balls (Martensite) | ≥52 | ≥49 | ≥4 | ≤2.0 | |

Package and shipment:

Related PRODUCTS

Contact Number:

Jinan ZenTi Heavy Industry Co., Ltd.

Tel: +86 17865316528

Contact: Kenny Li

Email: Kenny.Li@zentiheavyindustry.com

WhatsApp: +8617865316528