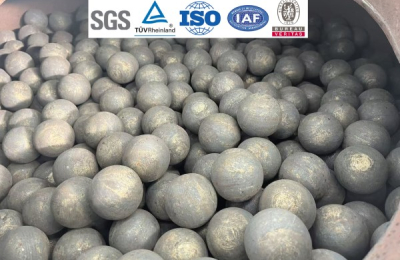

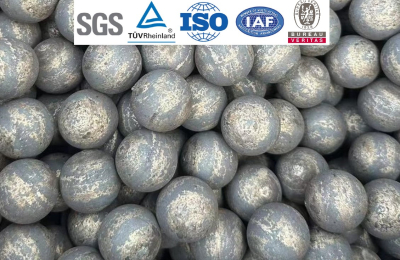

Forge Mill Balls

Forge Mill Balls are valued for their dependable performance, showing strong resistance to impact and wear during grinding operations. They maintain a consistent shape over long periods, reducing the likelihood of breakage and minimizing additional consumption. For mills aiming for high efficiency and low wear rates, these balls contribute to smoother grinding processes and more stable overall production performance.

Product Introduction

Forge Mill Balls are suitable for various mill types and mining conditions, offering a broad range of diameters to match different operational needs. Their uniform internal structure enables steady movement inside the mill, supporting more efficient grinding. With multiple size options available, mining operations can select the configuration that best matches their ore type and processing capacity.

Wide Application

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Forge Mill Balls are widely used in gold, copper, iron, silver and other mineral processing circuits. They are particularly effective in grinding stages requiring stable particle size control, helping reduce over-grinding and improving downstream classification and beneficiation. Whether in primary or secondary grinding, they deliver dependable performance that supports consistent plant operation.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Strict Quality Inspection

Every batch of Forge Mill Balls is subjected to strict inspections, covering hardness checks, appearance reviews, durability assessments and general performance tests. All data is carefully recorded to ensure batch-to-batch consistency. This level of quality control ensures the balls perform reliably under continuous mining operations, giving customers confidence in long-term application.

Manufacturing Process

Exhibition Presence

At major global mining exhibitions, we highlight our Forge Mill Balls and communicate directly with customers about their advantages and field performance. These events allow us to better understand the needs of various mining operations while strengthening connections with new partners. As our exhibition presence expands, more clients worldwide gain confidence in the stability and reliability of our grinding media.

Why Choose Us

Choosing our Forge Mill Balls means benefiting from consistent quality, timely delivery and long-term service support. With extensive manufacturing experience and sufficient inventory, we offer configuration guidance for different mill models to ensure smoother grinding operations. Thanks to our reliable product performance and professional communication, we have become a trusted partner for many mining operations worldwide.

Related News

Submitted successfully

We will contact you as soon as possible