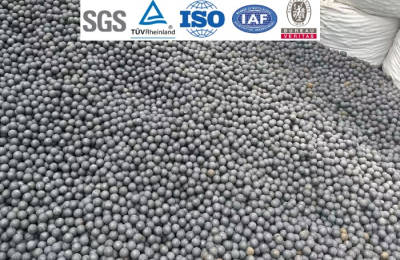

Forged Grinding Balls for Mining

Forged Grinding Balls for Mining deliver high wear resistance, strong impact toughness, and long operational life. Their uniform hardness and dense internal structure ensure reliable performance under heavy-load ball-mill conditions. With low breakage rates and stable grinding behavior, these balls help mining operations reduce media consumption and maintain consistent throughput even after extended use.

Product Introduction

Our Forged Grinding Balls for Mining are manufactured using carefully selected alloy steels and processed through controlled forging and heat-treatment procedures. The result is grinding media with balanced hardness and toughness, suitable for various ore types and grinding environments. Available in multiple diameters and sizes, these balls fit a wide range of mills used in mineral processing plants.

Wide Application

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Forged Grinding Balls for Mining are used across gold, copper, iron, and other metal ore grinding circuits, as well as in cement and mineral processing industries. They perform well in both dry and wet grinding conditions, and adapt to different stages of milling—from rough breaking to fine grinding. Their durability and versatility make them a preferred choice for large-scale mining operations.

Technical Performance

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Strict Quality Inspection

Every batch of Forged Grinding Balls for Mining undergoes rigorous quality inspection, including hardness testing, impact resistance evaluation, and dimensional verification. Our quality assurance process ensures each ball meets stringent standards for mechanical strength and wear life. This gives mining customers confidence in the reliability and longevity of the grinding media.

Manufacturing Process

Exhibition Presence

We regularly showcase our Forged Grinding Balls for Mining at international mining exhibitions around the world. These events allow us to meet clients face-to-face, present our grinding solutions, and gather feedback on different mining requirements. Through global participation, we strengthen our connections in the mining community and continuously improve our products to meet diverse demands.

Why Choose Us

Choosing our Forged Grinding Balls for Mining means choosing dependable quality, stable supply, and professional service. With years of experience supplying mills globally, we understand the needs of mining operations—and offer flexible sizing, timely delivery, and after-sales support. Our commitment to quality and consistency makes us a reliable partner for long-term mining projects.

Related News

Submitted successfully

We will contact you as soon as possible