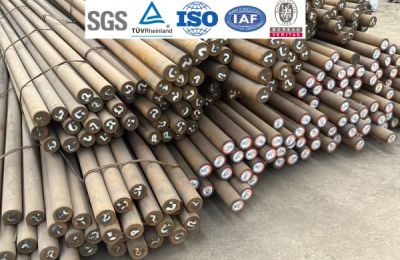

60mm Forged Grinding Balls

Our manufacturing process utilizes cutting-edge forging technology to produce 60mm Grinding Balls with exceptional quality. We start by selecting high-grade alloy steel, known for its durability and performance. The steel is then carefully heat-treated to achieve an ideal combination of hardness and toughness, ensuring the grinding balls perform optimally in demanding grinding operations.

Every single ball goes through a rigorous quality control process at each stage of production. From the initial raw material inspection to the final product examination, we meticulously check for consistency and durability. This thorough process ensures that each batch meets global quality standards, providing reliable performance in various industrial applications.

Product Overview

60mm Forged Grinding Balls are crafted from premium alloy steel and expertly forged to deliver exceptional strength and wear resistance. These balls are perfect for use in ball mills across multiple industries, such as mining, cement, metallurgy, and power generation. They play a crucial role in maintaining efficient grinding operations, minimizing the need for frequent replacements and reducing maintenance efforts.

Applications in Grinding Machinery and Industries

Machines | Industries |

·Ball mills | ·Mining industry |

·Power stations | |

·Tower mills | ·Cement industry |

·Coal grinding machine | ·Steel Industry |

·Bearing | ·Chemical Industry |

·Metallurgical industry |

Technical Specifications

Chemical Composition (%) | ||||||

Steel Specification | C | Mn | Si | Cr | S | P |

40Cr | 0.37-0.44 | 0.50-0.80 | 0.17-0.37 | 0.80-1.15 | ≤0.035 | ≤0.035 |

42CrMo | 0.38-0.45 | 0.50-0.80 | 0.17-0.37 | 0.90-1.25 | ≤0.035 | ≤0.035 |

60Mn | 0.57-0.65 | 0.70-1.00 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

65Mn | 0.62-0.72 | 0.90-1.20 | 0.17-0.37 | ≤0.25 | ≤0.035 | ≤0.035 |

ZT-4 | 0.44-0.72 | 0.50-0.90 | 0.17-0.37 | ≤0.50 | ≤0.035 | ≤0.035 |

ZT-10 | 0.60-0.78 | 0.65-1.33 | 0.25-0.65 | ≤0.45 | ≤0.035 | ≤0.035 |

B2 | 0.70-0.92 | 0.70-1.00 | 0.17-0.37 | 0.40-0.70 | ≤0.035 | ≤0.035 |

B3 | 0.52-0.65 | 0.66-1.00 | 1.30-1.90 | 0.74-1.20 | ≤0.030 | ≤0.030 |

B4 | 0.65-0.75 | 0.50-0.70 | 1.20-1.40 | 0.85-1.00 | ≤0.025 | ≤0.025 |

B6 | 0.75-0.90 | 0.80-1.02 | 0.17-0.37 | 0.88-0.98 | ≤0.035 | ≤0.035 |

BU | 0.95-1.05 | 0.95-1.05 | 0.15-0.35 | 0.45-0.55 | ≤0.035 | ≤0.035 |

BL | 0.55-0.75 | 0.65-0.85 | 0.15-0.35 | 0.70-1.20 | ≤0.035 | ≤0.035 |

BG | 0.90-1.05 | 0.35-0.95 | 0.15-0.35 | 1.00-1.70 | ≤0.035 | ≤0.035 |

Physical Features | |||||

Diameter (mm) (inches) | Surface Hardness (HRC) | Diameter Tolerance (mm) | Impact Value (J/cm²) | Breakage Rate (%) | Drop Test (times) |

20 (0.79) | >60 | +2.0 -1.0 | ≥12 | ≤1 | >15000 |

25 (0.98) | |||||

30 (1.18) | |||||

40 (1.57) | |||||

50 (1.97) | |||||

60 (2.36) | +3.0 -1.5 | ||||

65(5.56) | |||||

70 (2.76) | |||||

75 (3.00) | |||||

80 (3.15) | |||||

90 (3.54) | |||||

100 (3.94) | +4.0 -2.0 | ||||

120 (4.72) | >58 | ||||

125 (4.92) | |||||

140 (5.51) | >55 | +5.0 -3.0 | |||

150 (5.91) | |||||

Advanced Quality Control and Inspection Systems

Facilities and Production Machinery

Exhibitions

Why Choose Us

We understand that each industry has unique needs. That's why we offer customized grinding balls designed to meet your specific requirements, ensuring efficiency and performance in your grinding operations.

Our experienced team is dedicated to delivering high-quality products backed by years of expertise. We work closely with our clients to understand their needs and continuously improve our products to meet the latest industry standards.

Related News

Submitted successfully

We will contact you as soon as possible